NUNOUS by Seishoku

Upcycled material

NUNOUS | Seishoku

DESIGN NOTE

New upcycled material made from substandard fabric

Unique natural stone-like look of laminated fabric

photography : NUNOUS

words : Reiji Yamakura/IDREIT

NUNOUS is an upcycled material with a unique organic pattern, developed by the Okayama-based dyeing company Seishoku Co., Ltd. They use substandard fabrics that they previously discarded to manufacture NUNOUS.

When we asked Akira Himei, CEO of Seishoku, why they developed this product, he said, “We dye and process around 1 million metres of fabric per month, and every month a certain amount of cloth becomes substandard. We thought it was a waste to throw away material that was still usable. The fabric uses labour, fuel and dyes to dye it, and it also costs more to dispose of them. Our first idea was to make use of fabrics that didn’t meet the high-quality standards.

Seiichiro Nishizaki, who was in charge of the development, said, “We thought we could open up a new market by creating a material that could be used in other fields, rather than just using as cloth. That’s how we came up with the idea of hardening it into a board. At first, we tried adhesives, but they didn’t work. After consulting with local engineers of the Industrial Technology Center of Okayama Prefecture, we developed a polymer moulding method and succeeded in solidifying it. We also discovered that the cutting surface was beautiful, and that was around 2014.”

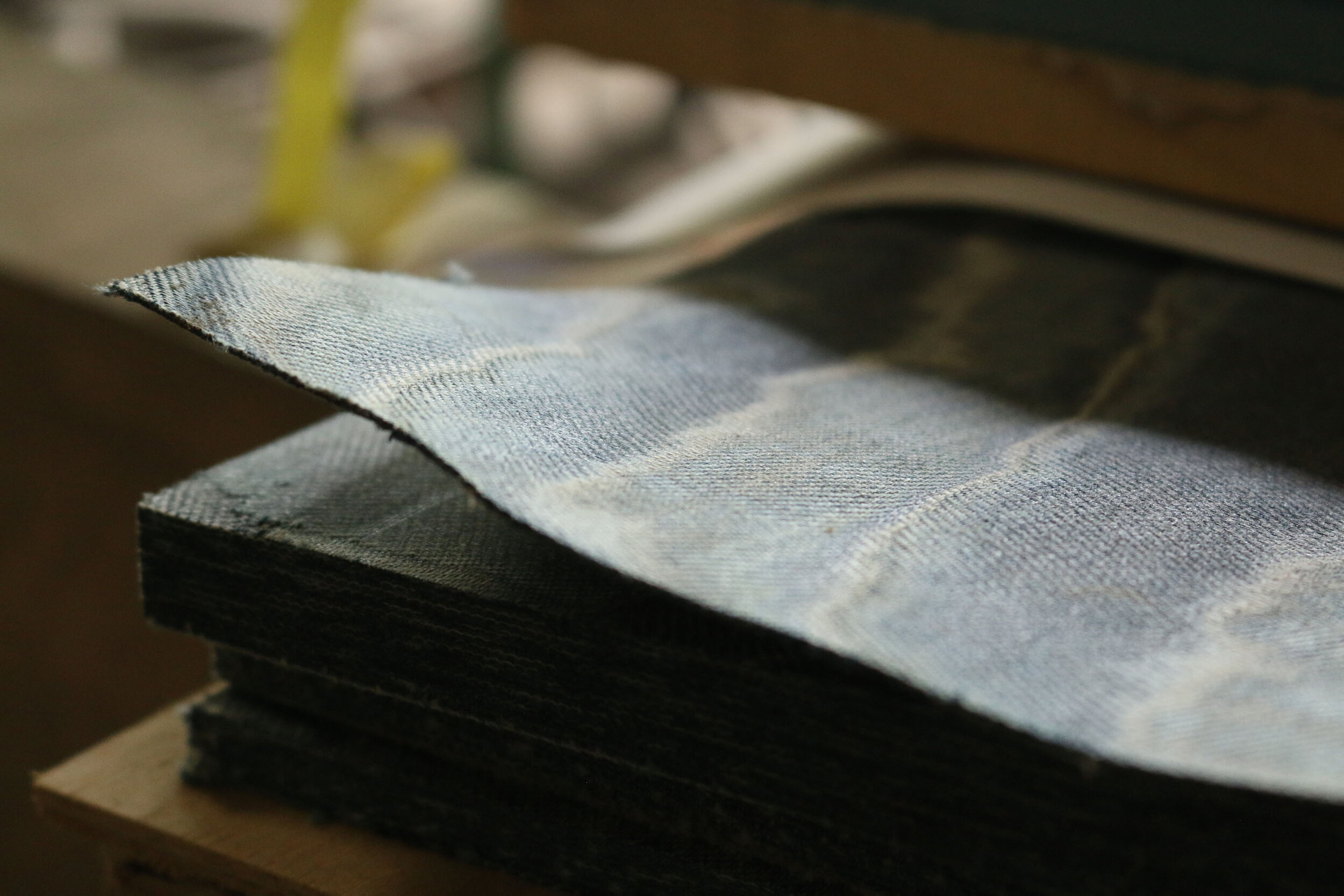

From that stage, further trial and error followed before they realised the current pattern. “At the time, sound-absorbing felts made from crushed fabric were known as recycled material. To make a difference to them, we decided to focus on design in our material development. So we offered to collaborate with the design department of Okayama Prefectural University and kept testing. In the process, we discovered a beautiful pattern that appears when slicing in the layering direction,” said Nishizaki.

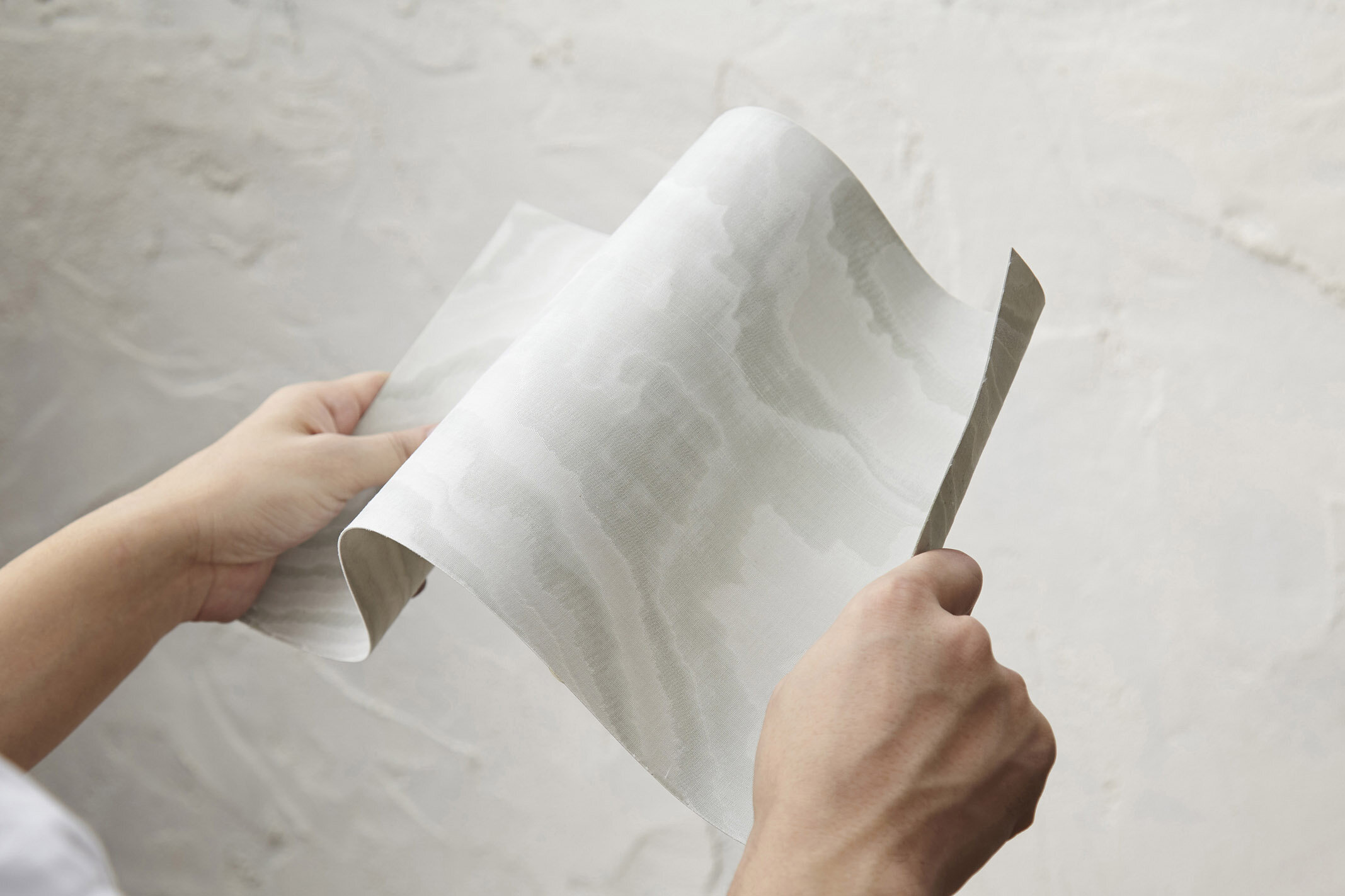

The unevenness of the fabric gives a unique pattern when it is cut. Technically, the success in processing it into thin, veneer-like slices has made it practical. Then, in April 2020, they named their new material NUNOUS, from the words NU (=new), NUNO (=cloth) and US (=tomorrow), and officially released it. At present, two types are available: STONE in board form and SKIN in sheet form.

Satoshi Itasaka has designed ‘Stump chair’ with STONE. photography: h220430

STONE was chosen by the architect Satoshi Itasaka as the material for his Stump chair, a chair representing a social statement, and exhibited at DESIGNART TOKYO 2020.

At the end of the interview, we asked them about the plans, “Initially we were planning to sell overseas, but due to covid-19, we are now trying to promote it in Japan, in the field of architecture, interior design and products. We can also use local textiles, and we want to encourage designers to use it as art panels and fixtures. In today’s world with SDGs, we believe that upcycling cloth is not only necessary for the textile industry but also society. So we want to open up a new market with NUNOUS and spread it as a common material,” said Himei, Nishizaki and Risa Sagane from the team.

NUNOUS is a unique material that contributes to waste reduction, a critical issue in modern life, and at the same time, meets the requirements of designers.

The art panel made of NUNOUS was installed in the hotel ‘GRAND BASE Okayama-ekimae. photography: NUNOUS

At the entrance hall of Shimada Shoji, a denim-made NUNOUS panel was installed. photography: NUNOUS

DETAIL

By slicing parallel to the layers of fabric, a unique pattern appears on the surface, which looks like a marble or plain-sawn timber.

The success of the thin veneer-like processing was a breakthrough for practical development.

A prototype of laminated glass with NUNOUS SKIN. They used a sheet of NUNOUS SKIN made of denim.

CREDIT + INFO

Name: NUNOUS

Manufacturer: Seishoku Co., Ltd.

Material: substandard fabrics + polymer

Maximum size:

STONE 450mm x 450mm t48mm (Minumum thickness 4mm)

SKIN 450mm x 225mm t1mm (Minumum thickness 0.3mm)

Colour:

light-grey, blue-green, lilac, greysh-green, grey, light-navy, navy, black, denim (indigo)